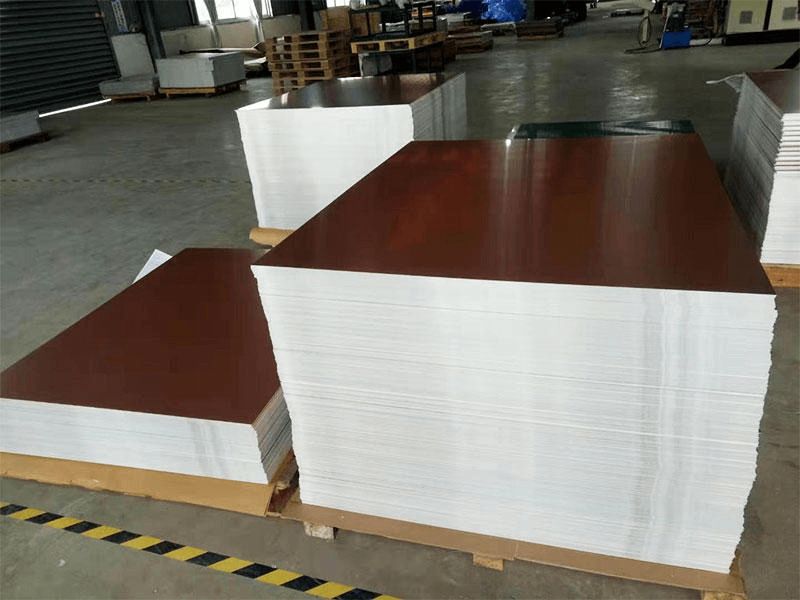

Aluminum Copper Clad Laminate

DK Enterprise is a leading Aluminum Copper Clad Laminate Supplier located in Ahmedabad, Gujarat manufacturing and merchandizing in high-quality Aluminum Copper Clad Laminate Sheets and panels for 10+ years now. Our wide range of products is quite acknowledged by our clients for their excellent electrical insulating properties, adhesion, and heat resistance.Our Aluminum-backed PCBs can constantly enhance durability and longstanding reliability of a final product via temperature control and related decreases in failure rates. Moreover, the aluminum designs also deliver better mechanical solidity and lower thermal expansion levels compared to any other available materials.

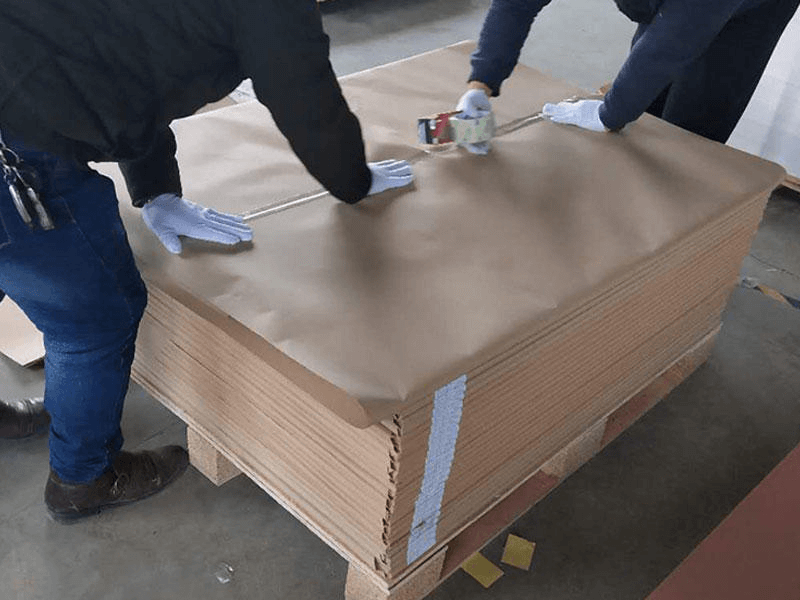

The end-to-end product range that we supply is derived from reputed vendors across the globe. By leveraging cutting edge technologies, best-grade of factor inputs, and strict quality inspection we deliver products that meet international quality standards.

How Is Aluminum Copper Clad Laminate Made?

The aluminum bar is totally melted into an aluminum liquid and put into a furnace for standing. After filtering aluminum liquid, it penetrates the composite zone where the copper sheets are directly placed to let it touch the surface of aluminum liquid for bonding. Our Aluminum copper clad laminate sheets are manufactured as per the IPC standard and following an advanced process to deliver improved product quality at reduced costs.

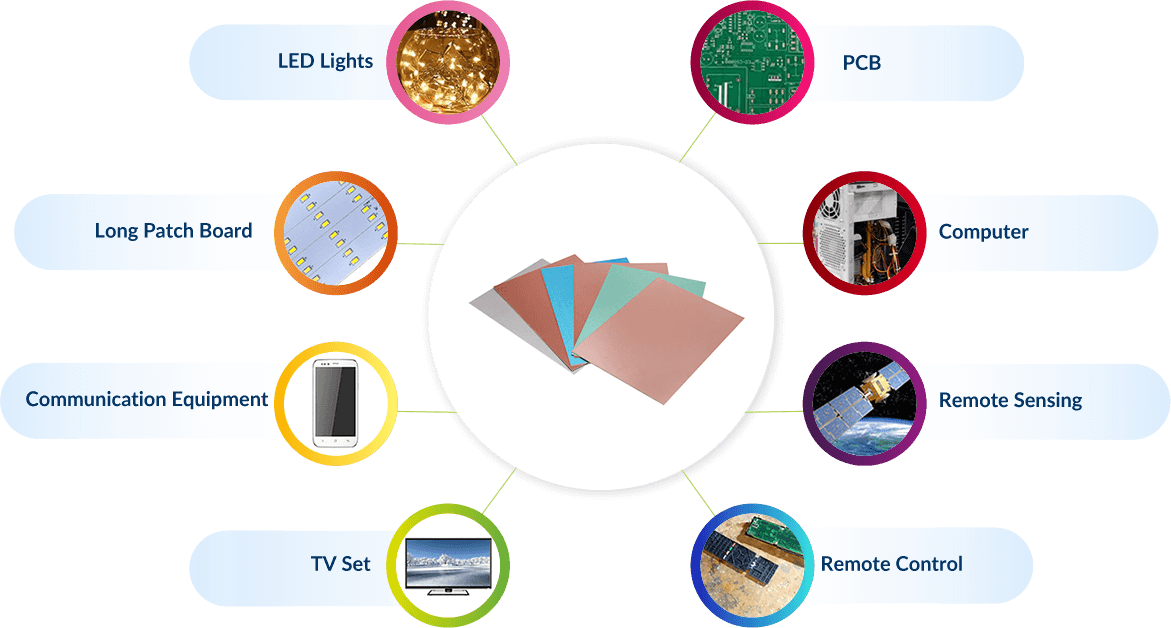

Some Of The Applications Of Aluminum Copper Clad Laminate

- High power LED

- Car headlights

- Home appliances

- LCD TV and soundbox

- Modifier and sparker for motorcycle and mobile devices

- Advanced electronic products

- High-density circuit board

- Three-dimensional space circuit assembly

- Circuits and the shell integration assembly

- Electromagnetic shielding and more

Features Of Aluminum Copper Clad Laminate

- Excellent flame retardant

- Good heat resistance

- Excellent in thermal conductivity

- Good electromagnetic shielding and solder float

- High mechanical strength

- Very light in weight

- Top-notch machining properties

- Quite cost-effective